The Swedish iron and steel industry is already climate-efficient in international comparison, but that is not enough.

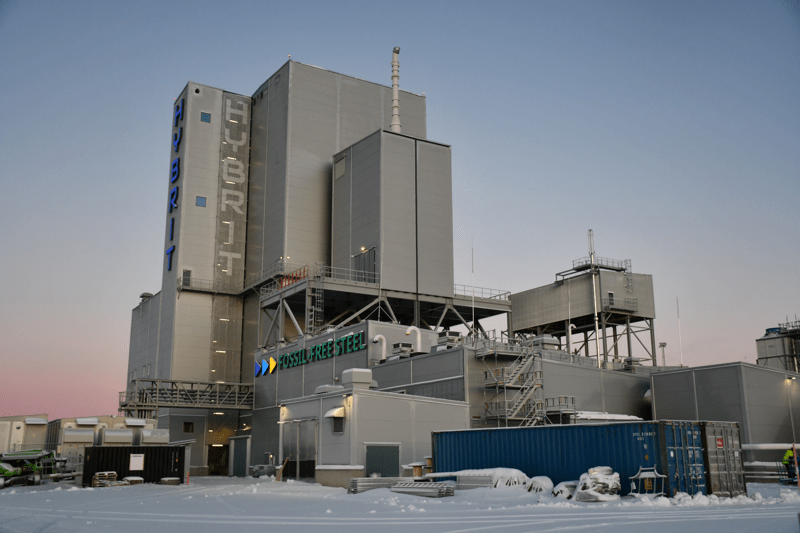

In 2016, SSAB, LKAB and Vattenfall started the HYBRIT® initiative (Hydrogen Breakthrough Ironmaking Technology) with the aim of creating a completely fossil-free value chain from mine to fossil-free steel, with fossil-free pellets, fossil-free electricity and hydrogen.

The steel industry currently accounts for about ten percent of Sweden's carbon dioxide emissions and seven percent of global emissions. HYBRIT® is helping to change this through ongoing research and innovation.

On 31 August 2020, the pilot plant for direct reduction of iron ore with hydrogen was commissioned and in August 2022, the pilot plant for storage of fossil-free hydrogen was commissioned.

The HYBRIT® technology, validated and optimized over several years of development with very promising results, will now be used and further developed in industrial applications on a larger scale.

About Hybrit Development AB

In 2016, SSAB, LKAB and Vattenfall started the HYBRIT® initiative (Hydrogen Breakthrough Ironmaking Technology) with the aim of creating a completely fossil-free value chain from mine to fossil-free steel, with fossil-free pellets, fossil-free electricity and hydrogen.

The HYBRIT® technology, validated and optimized over several years of development with very promising results, will now be used and further developed in industrial applications on a larger scale.

Already working at Hybrit Development AB?

Let’s recruit together and find your next colleague.